Is One Weak Link Slowing Your Team Down?

In a factory assembly line, the entire production process halts if one machine breaks down. The Theory of Constraints tells us that any system is only as strong as its weakest link.

Examples:

1. In software development, a slow code review process can delay the entire project.

2. In manufacturing, one slow machine can delay the entire assembly line.

3. In customer support, slow response times can frustrate customers and damage your reputation.

How to address this the theory of constraints?

1. Understand that any process will have at least one constraint that limits its performance. Identify that constraint in your workflow.

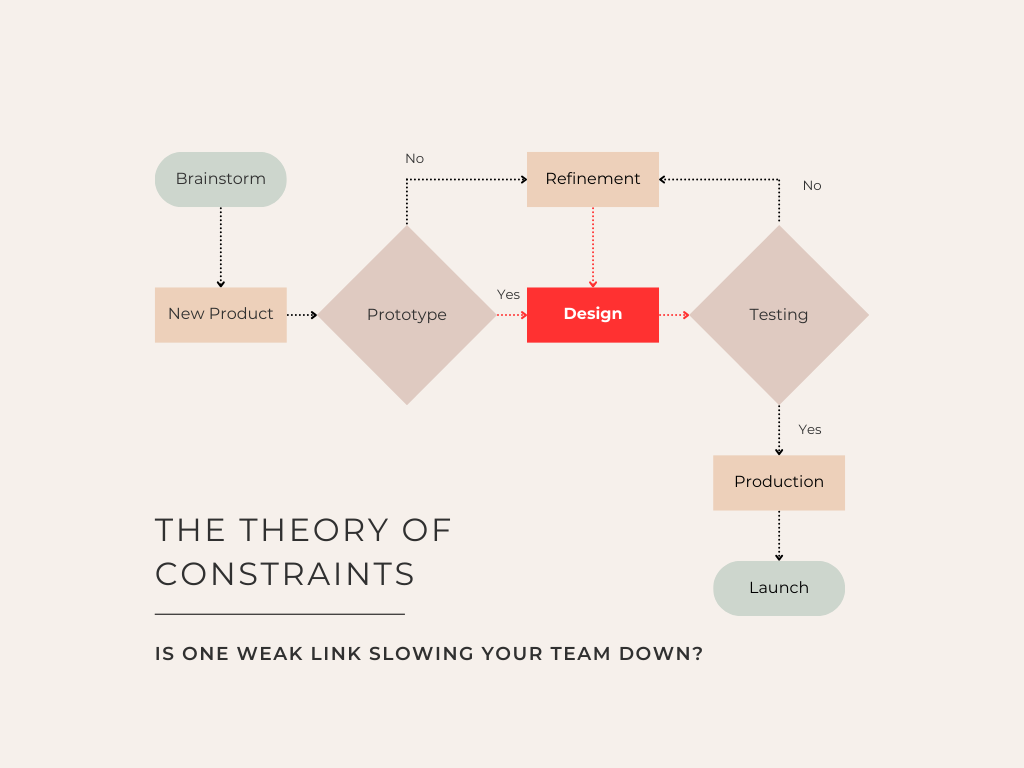

2. Find the weakest link in your process and focus on improving it. Use flowcharts to visualize and identify bottlenecks.

3. Constraints can shift over time, so ongoing monitoring is essential. Implement regular check-ins and reviews to monitor workflow efficiency.

Are bottlenecks slowing down your workflow? How have you addressed the bottlenecks?

The Theory of Constraints